BluKote Lining

![]() Line

Line

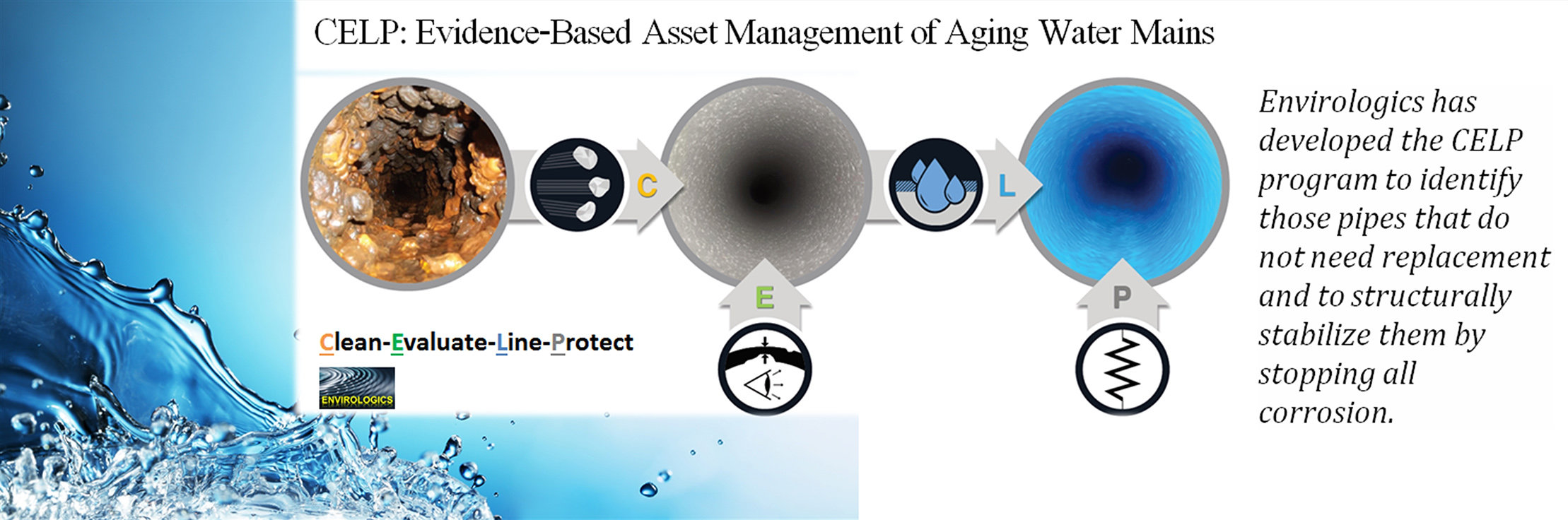

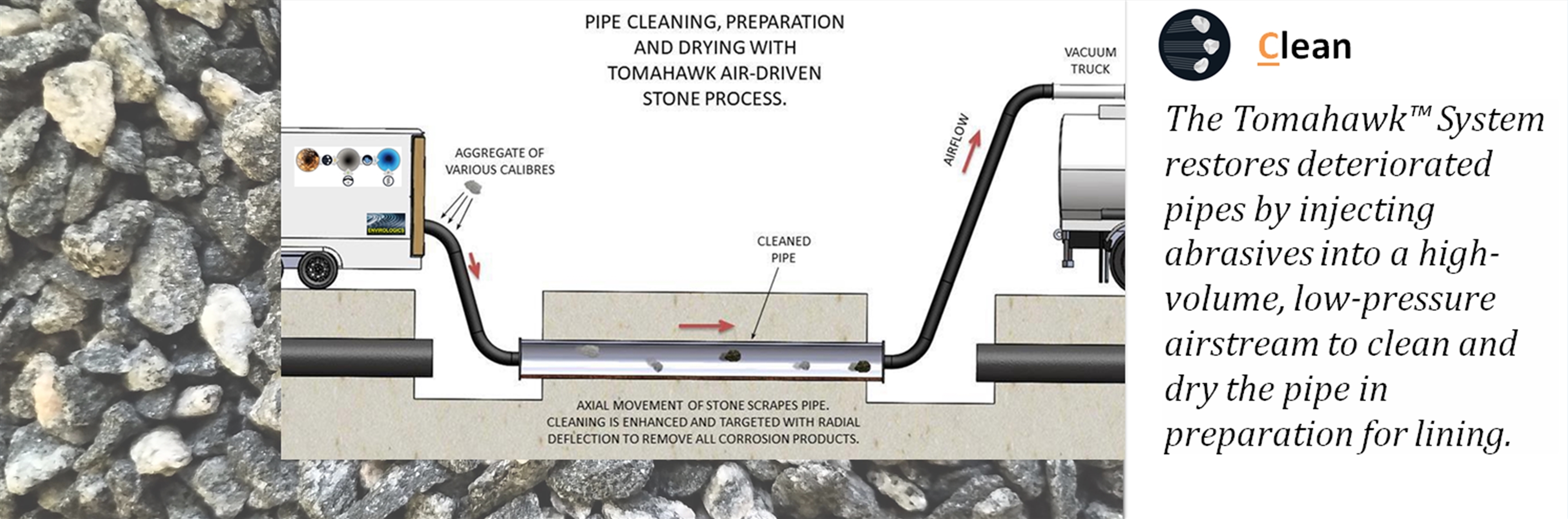

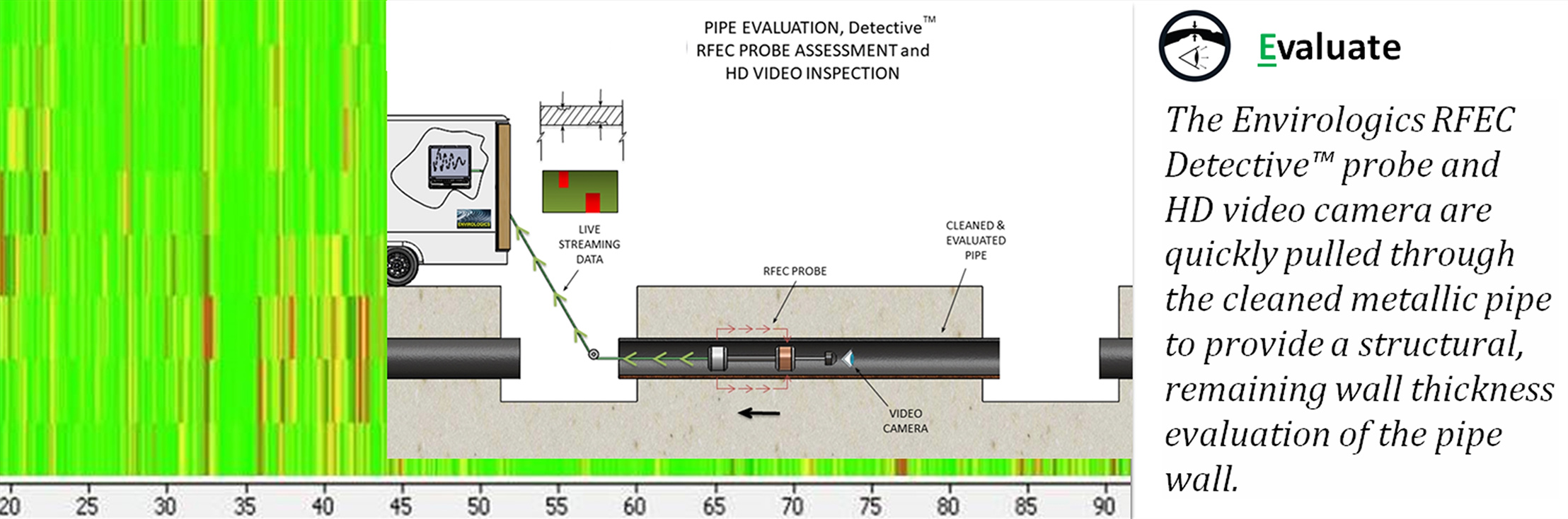

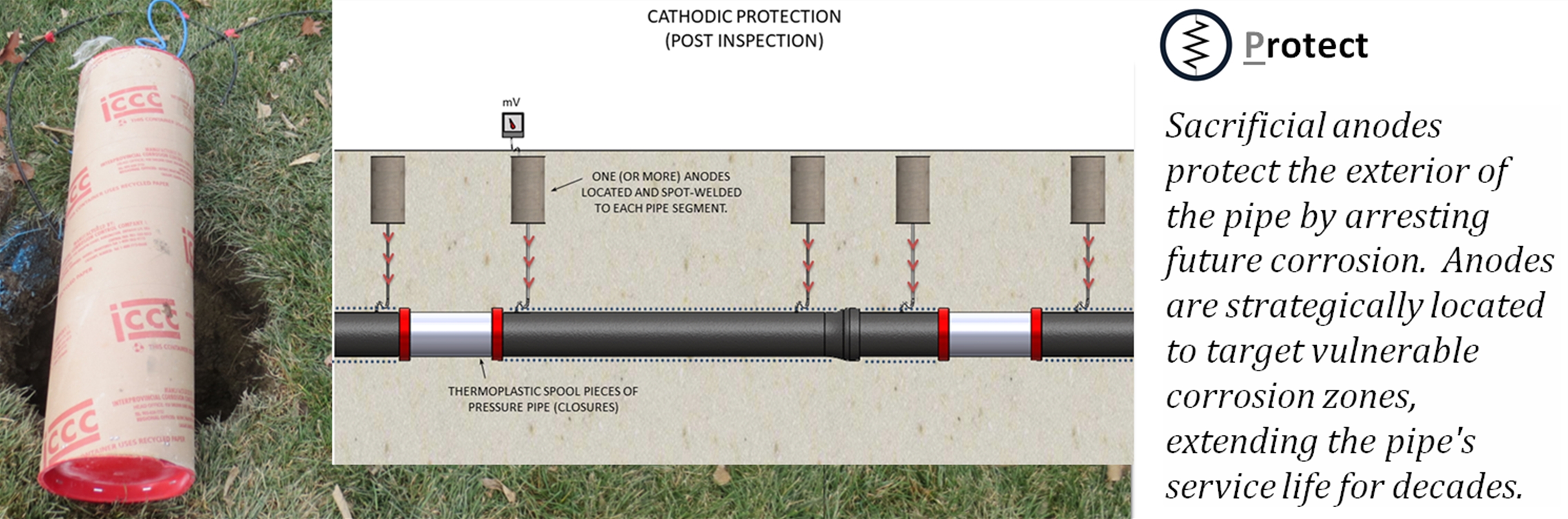

Following Tomahawk cleaning, preparation and pipe evaluation, any lining technology can be applied to the pipe wall, including CIPP (cured-in-place pipe) or SIPP (sprayed-in-place pipe) technologies. However, the optimal lining technology choice depends on the structural condition of the pipe determined during pipe evaluation.

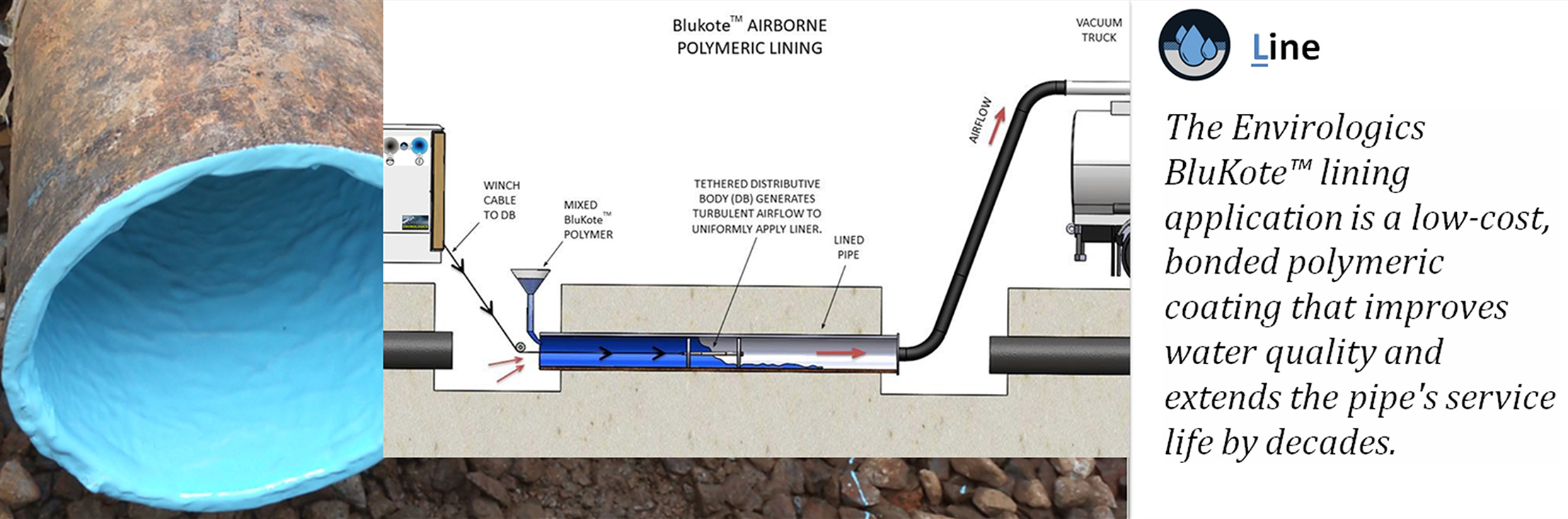

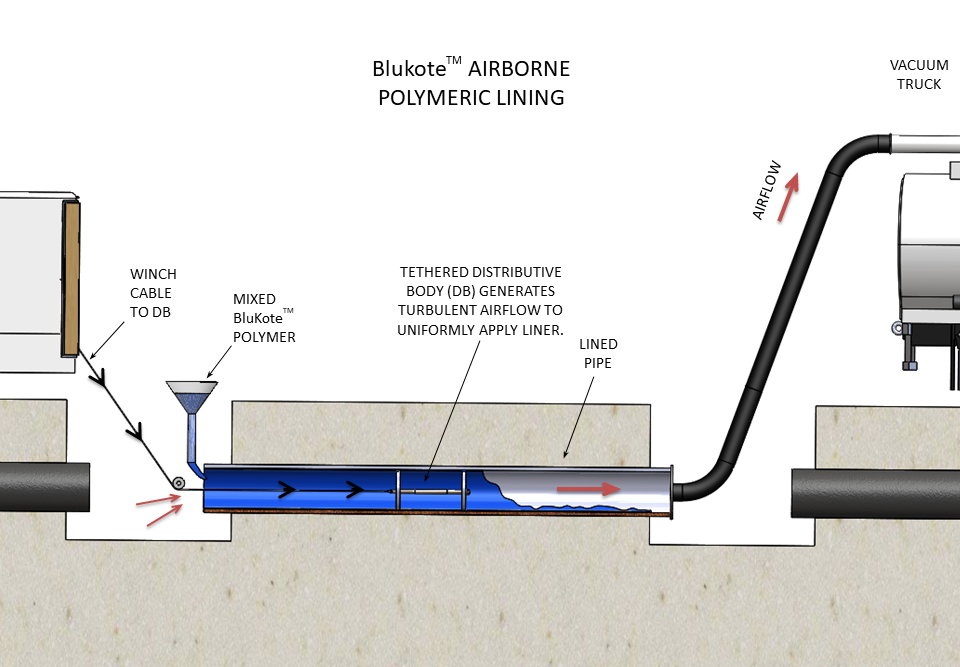

Envirologics now offers our proprietary airborne lining solution called BluKote. This application is a fast, lower cost, non-structural, AWWA Class I barrier coat to improve water quality and flow rate while extending the pipe's service life by decades. The BluKote airborne lining process uses a vac truck generated airstream within the pipe to apply the lining material.

The BluKote process is capable of lining pipes 100mm (4") up to 100m (330') long, 150mm (6") and 200mm (8") up to 120m (400') long. The average coating thickness is 0.75 to 1.0mm per pass. BluKote is NSF/ANSI 61 certified for contact with drinking water. Click here to view the BluKote technical datasheet. For a BluKote overview document which includes material application, vac tuck, access pit specifications and more, please click here.

Above, Envirologics Blukote Airborne Lining Schematic.

Above, Envirologics Blukote Airborne Lining Schematic.

For a video overview of the BluKote airborne lining technology, please click here.

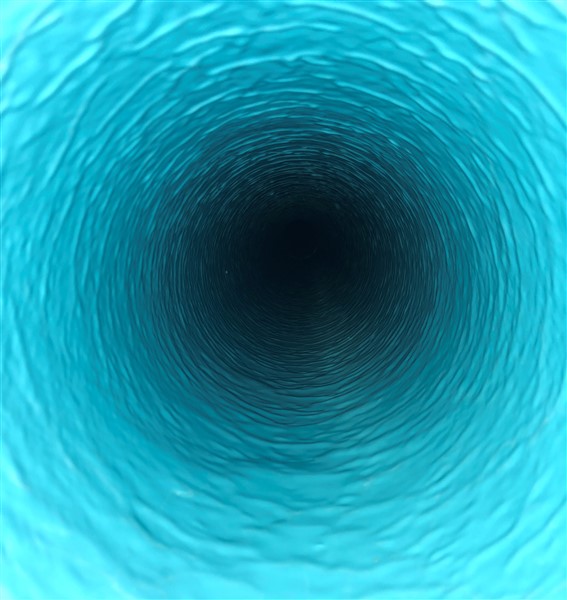

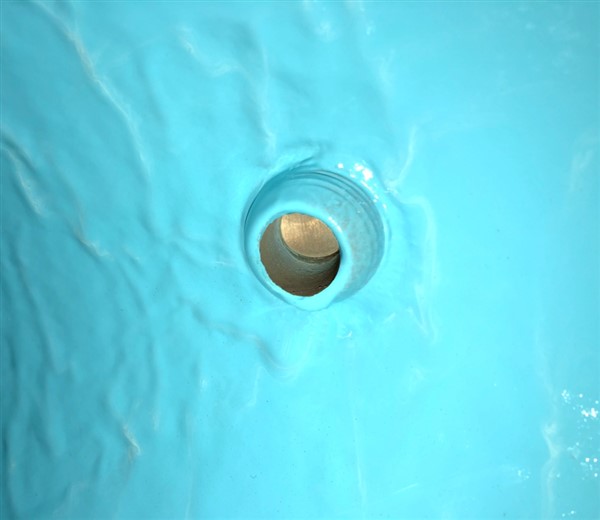

Lining Results

The lining application produces significant flow improvements due to C-factors > 110. The service connection shown below is fully coated with no voids or shadows around the exterior. Material does not fill or block the unobstructed service. The BluKote liner is continuous and fully bonded in this crucial location. Pipe joints are fully coated and often filled for a countinuous liner, providing excellent results.

Additional Resources

For additional information on our Tomahawk™ System and BluKote lining such as videos, articles, presentations and brochures, please visit our resources page.