Watermain Lining and Tuberculation Explained

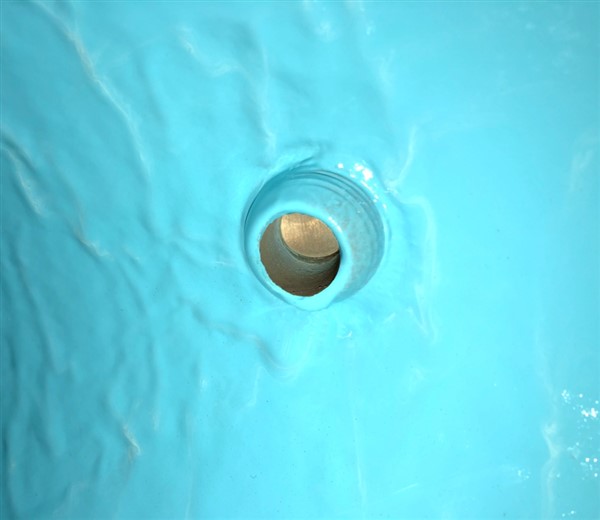

Tuberculation

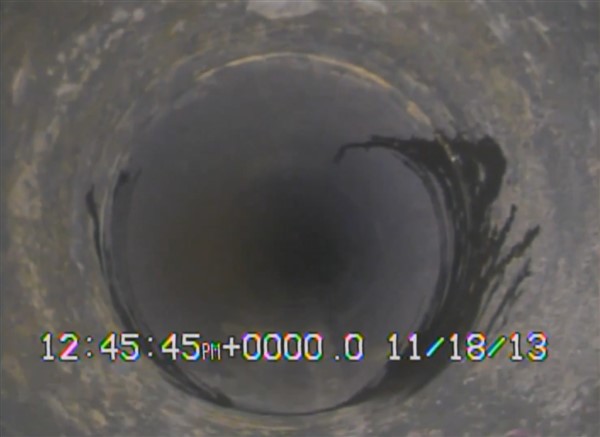

Tuberculation is the formation of nodules rich in iron oxides due to the corrosion of steel and cast iron water main piping, sometimes with the assistance of iron bacteria. These tubercules are made primarily of iron oxides with some portions of other minerals, carbon, and silica compounds. The growth of this corrosion not only affects the structural integrity of the pipe, but it grows inwardly affecting water quality, flow through service connections, and hydraulic capacity (leading to high pumping losses), and the high frequency of pipe breaks in the news. The porous and rough nature of the tubercules could also shelter bacteria and parasites in the watermains. Tuberculation in uncoated pipes is rampant, but it is often seen in conjunction with old failed or tired lining materials.

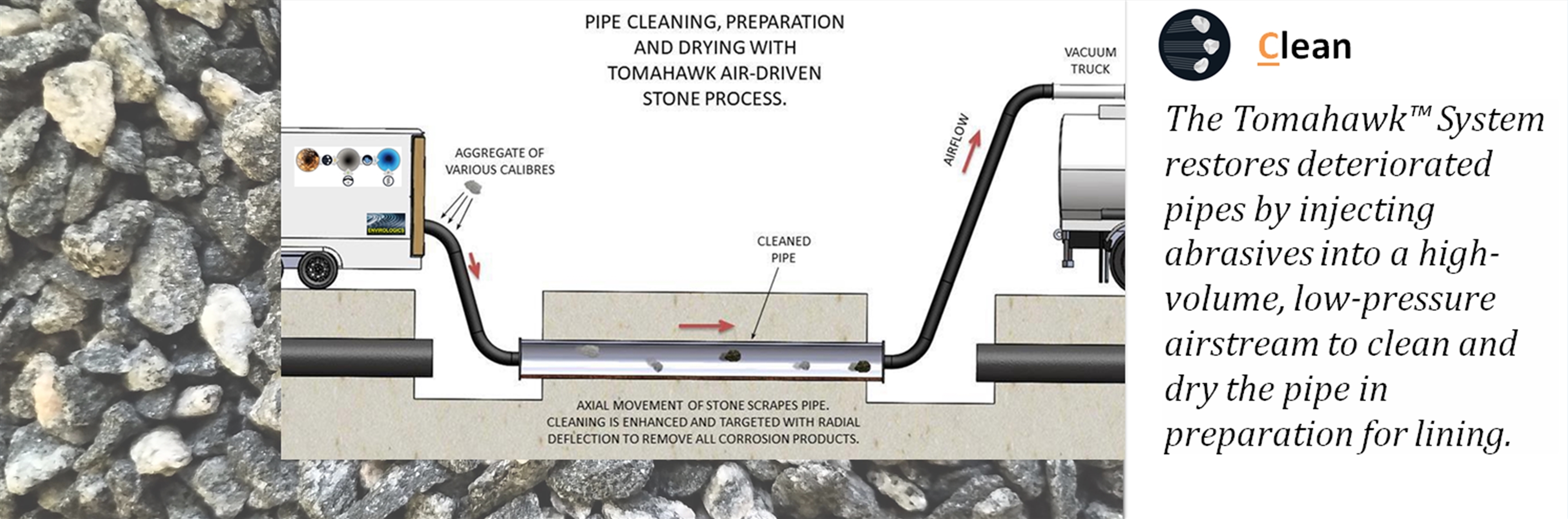

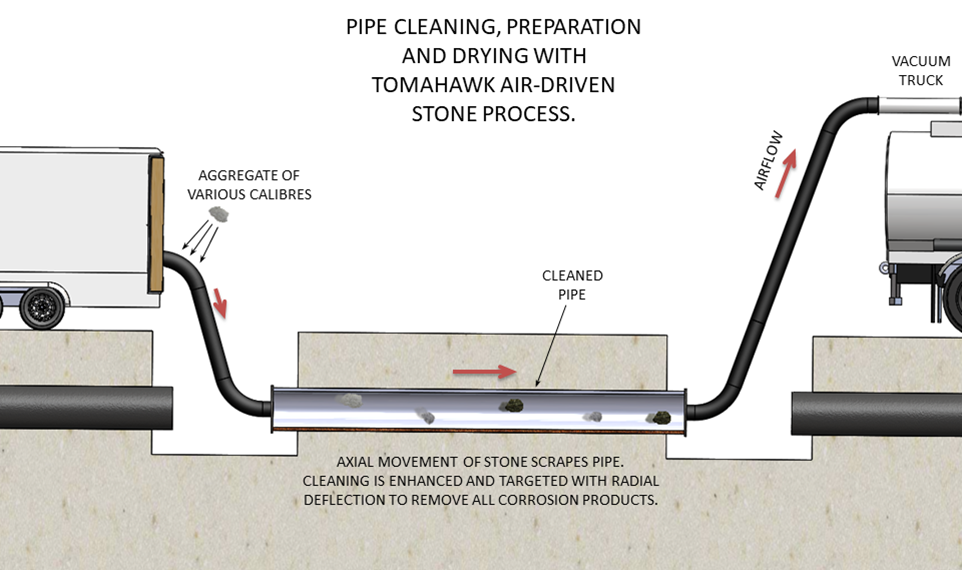

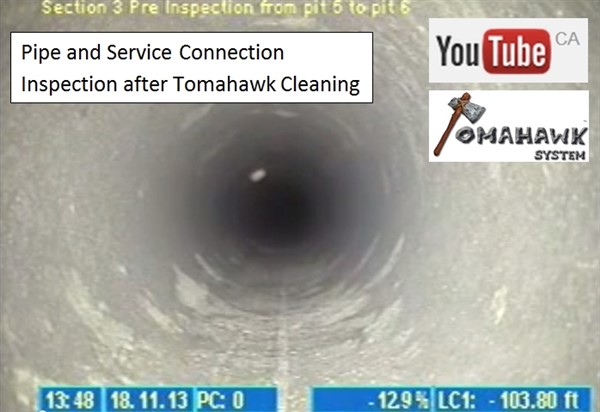

The Tomahawk System™ can quickly remove tuberculation from water mains and prepare the pipe for maximum liner bond!

Tomahawk Tuberculation Removal

Bitumen Lining

Bitumen lining is a process that has been used since the first iron pipes were produced, basically an asphalt coating. It is a petroleum product, separated as the bottom-most and most dense of the crude oil components in fractional distillation. It is quite hard at ambient temperatures and it must be heated or thinned using ethyl alcohols or surfactants in order to be flowed or pumped. It was, and is, routinely applied to the interior and exterior of the pipe. The interior of potable water pipes is still often coated using an application of heated liquid bitumen lining. Though the coating is fairly effective at preventing corrosion it is also a very difficult to remove by conventional methods, as many in service pipes have failed liners.

The Tomahawk System™ is the only method proven to remove these types of linings and prepare the pipe for maximum bond.

Coal Tar Lining

The first documented use of coal tar in the corrosion prevention of potable ferrous water pipe was 1914 in New York City. They were designed for and have provided 50+ years of service to the municipalities who installed them. The lining is a mixture of coal gas and coke production by-products, powdered coals, flux oils, and inert fillers of talc and slate powder to increase flexibility and strength. Though CTE lining was discontinued in the 1960s due to microbial water quality and aromatic carcinogen concerns there are still pipes in the ground just past double their design life. The problem is that when there is a break in this lining (as with any lining) the corrosion will begin to attack the pipe and strip the lining from its surface, forming tuberculation.

The Tomahawk System™ can remove coal tar linings from water mains eliminating the public health concern and restoring water quality to customers.

Portland Oregon Coal Tar Lining causes foul odour

Asbestos Cement Pipes

Chrysotile Asbestos Cement Pipes are made by rolling a slurry of Asbestos and Portland cement into a hoop around a mandrel. The Asbestos fibre makes a superior concrete product and was used in the creation and maintenance of potable water mains and sewers from 1920 to the late 1980's when they were banned by the EPA in the US. These pipes are not subject to tuberculation or significant hydraulic losses; however they suffer from a chemical leeching of calcium into the water supply, slowly depleting the integral component in the structure of the cement. The leeching is a diffusion process affecting the exposed surfaces first and most rapidly. As the interior of the pipe releases calcium, the inner layer of Asbestos fiber is also loosened allowing some Asbestos fibers loose into the water stream. This also forms a porus surface allowing microbial growth and adversely affecting water quality. The majority of asbestos Cement pipes still have acceptable wall thickness, but suffer from a linear degradation over time.

There are estimated to be over 300000 miles of AC pipe installed in the U.S.A. today. Many of these pipes could be tested, cleaned, dried and have a Water Quality coating applied, extending pipe life and eliminating internal calcium leeching, and asbestos fiber release.

The Tomahawk System™ can quickly and gently remove loose wall material to prepare and dry asbestos cement pipe in preparation for lining. The Tomahawk System™ also captures all asbestos fibre waste using current, approved abatement methods.