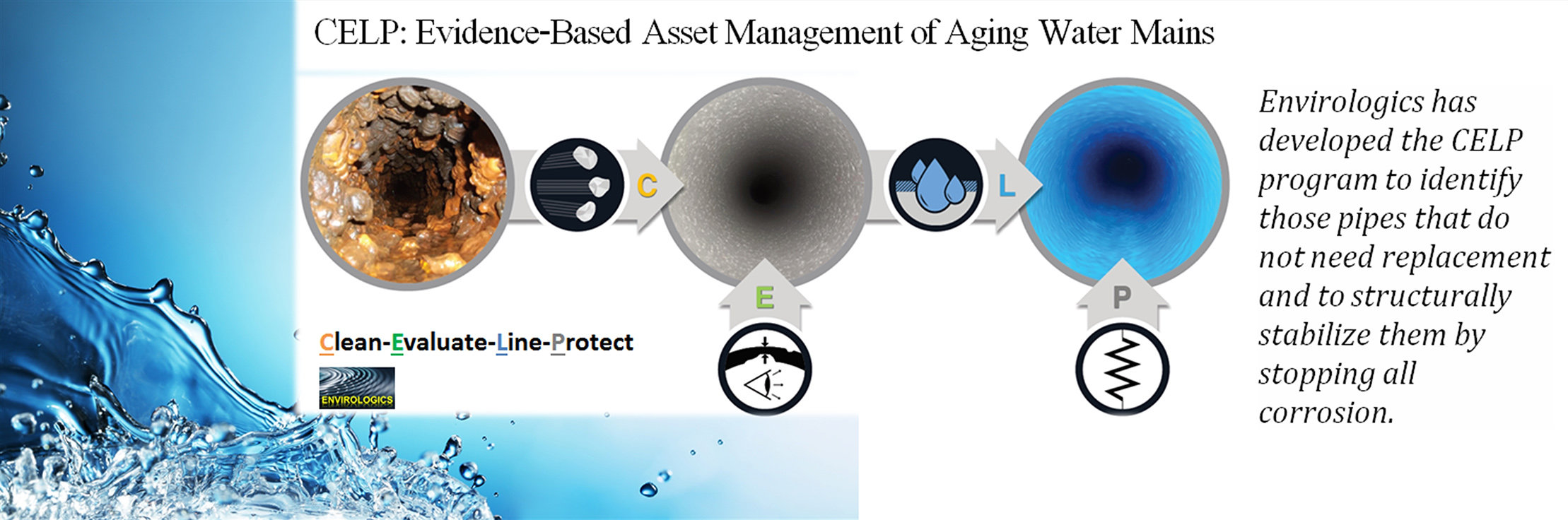

October 23, 2018 - Tomahawk Cleans and Lines 100mm (4”) Service Pipe to Building at CNL, in Chalk River, Ontario

Pre-Project Condition:

This project contained a 100mm (4”) cast iron water service main into a building carrying both potable and fire water. The pipe was highly tuberculated causing flow rate and pressure concerns especially for fire-fighting purposes.

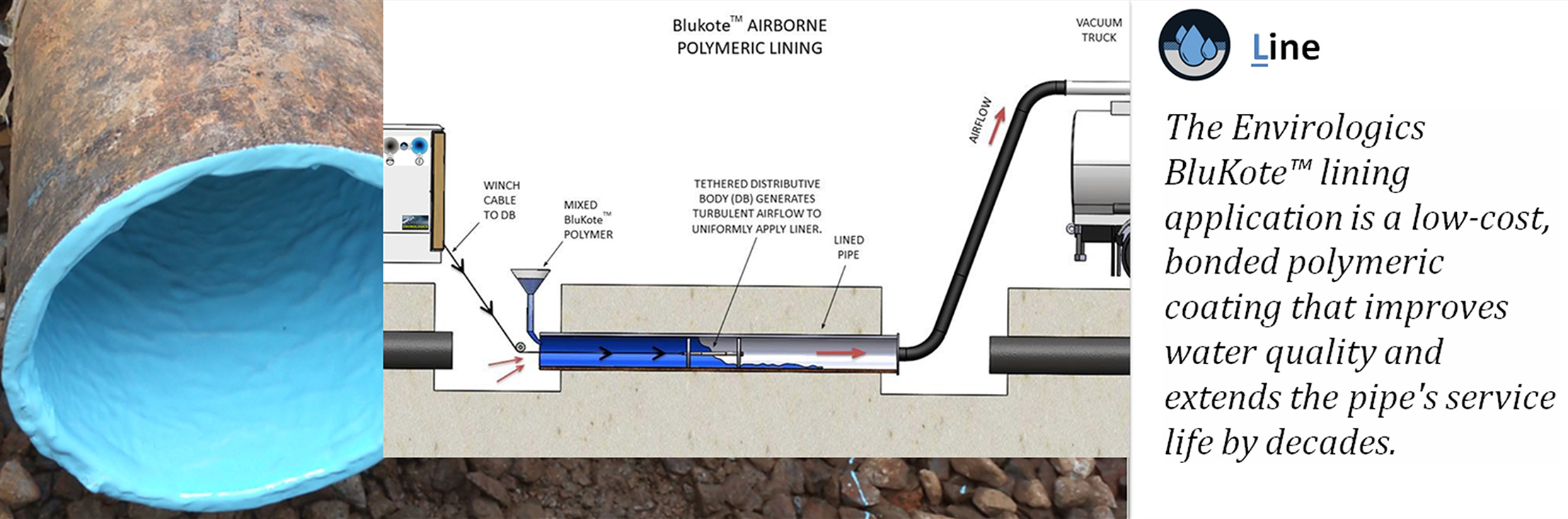

Pictures: Above left, interior (vertical) end of water service line before cleaning, center, after cleaning, right, after lining with Tomahawk BluKote™.

Project Details

Location: Canadian Nuclear Laboratories, Chalk River, Ontario

Tomahawk Licensee: Envirologics Engineering Inc.

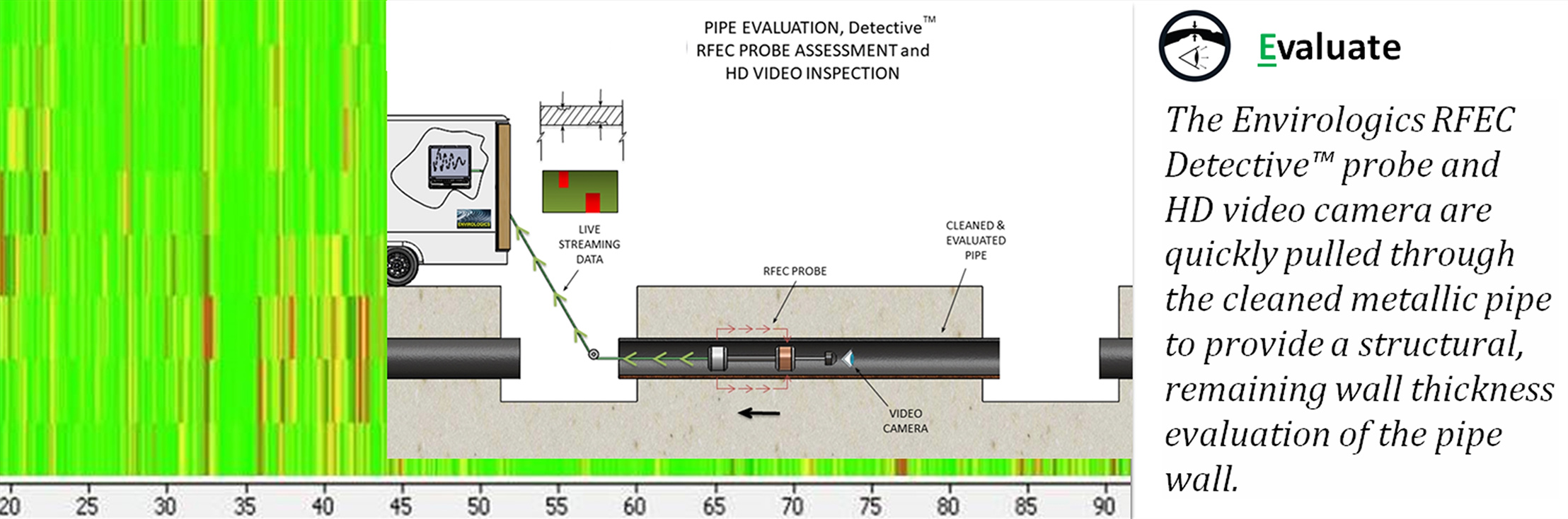

Pipe Details: The pipe was structurally sound. Pipe consisted of a horizontal buried pipe leading from the watermain service, under the building foundation, 90° of vertical bend, then up through the building’s interior floor

Pipe Size, Material: 100mm (4"), Cast Iron

Pipe Age: 45 years

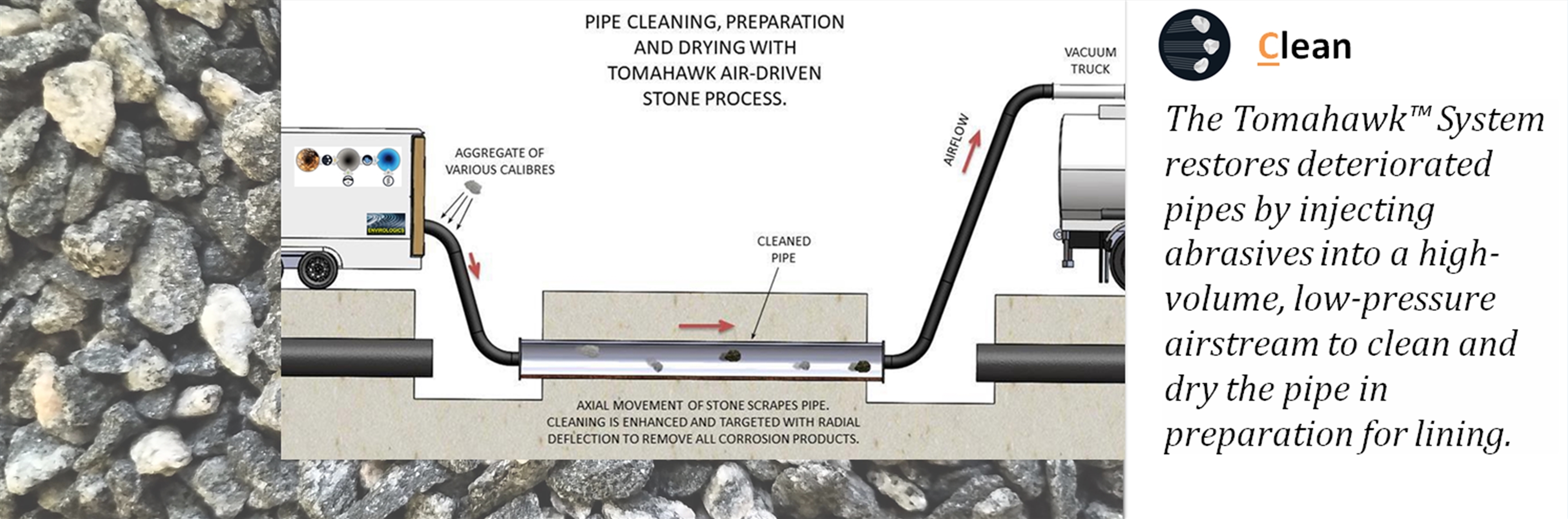

Cleaning Technology: Tomahawk™ System by Envirologics

Lining Technology: Tomahawk airborne lining, BluKote™

Results: Water flow rate was restored to original design, improving potable and fire flows. The pipe’s useable life was extended by decades. Tomahawk’s insitu pipe rehab process eliminated the need to dig-up the building’s floor and foundation to replace pipe.

Pictures: Above left, cleaning operations outside of building, above top right, exterior horizontal end of pipe after cleaning, lower right, after lining with Tomahawk BluKote™.

For more information about Tomahawk cleaning and lining, contact us at This email address is being protected from spambots. You need JavaScript enabled to view it. or 1-800-267-9810.